It is acknowledged that a good package brings numerous advantages to products. In order to ensure good packaging, inspection is an indispensable link in the whole packaging process. And here comes the inspection machines. Inspection machines play an important role in the pharmaceutical packaging industry. In order to prevent defective products from entering the market, ampoules, vials, and oral liquid vials all need to be inspected for particles, caps, cracks, and levels.

So, how to choose a qualified inspection machine? Please keep reading to get the latest information about buying inspection machines.

Contents

About Inspection Machine in Pharmaceutical Industry

An advanced packaging technology includes advanced inspection for certain. Here are the top 5 things you should pay attention to when buying inspection machines.

● Inspection Precision of the Machine

With billions of doses injected and medicine worldwide each year, there is an increasing demand for reliable, efficient, and technologically advanced automatic inspection machines. And quality inspection involves a complete assessment and testing of medicinal products to ensure that they meet the required standards. Among all the performances of an inspection machine, inspection precision is the most important one because the safety of the user is at stake, the drug in a package, whether liquid or pellet, must be very accurate.

Besides, the precision of the inspection machines includes the precision of product content, expiry, quality, and quality variation.

● Efficiency of the Machine

The efficiency of the machine is also an important consideration. Every day, the pharmaceutical industry produces large quantities of medicine, most of which are in small bottles. The problem is how to efficiently examine a large number of vials. For example, the speed of the machine may need to reach hundreds of tests per minute to meet customer requirements.

● Risk of False Reject

Of course, in the pharmaceutical industry, where mass production takes place every day, there are bound to be a few substandard products. Usually, the lid, body, and base of the vial or ampoule are prone to unqualify, and the intelligent automatic inspection machine will automatically reject unqualified products. In the inspection process of a machine, every link has the possibility of error. So is automatic rejection. If a machine is at risk of wrongly rejecting a medicine, it can affect the medicine manufacturer’s production schedule. Because one mistake leads to a second, manufacturers can lose a lot of qualified medicine.

● Technology Capability

Technology capability is another measure of packaging machine manufacturers. Only packaging machine manufacturers with scientific and technological capabilities can improve product quality, such as how to ensure no leakage in case of bottle damage, how to enable operators to clean quickly and safely and improve work efficiency.

● Customized Service

Last but not least, customized service is of every customers’ concern. Pharmaceutical manufacturers need to choose a range of bottle sizes and speeds that are appropriate for their own particular bottle. So you need to find a packaging machines manufacturer that makes it specifically for your operation.

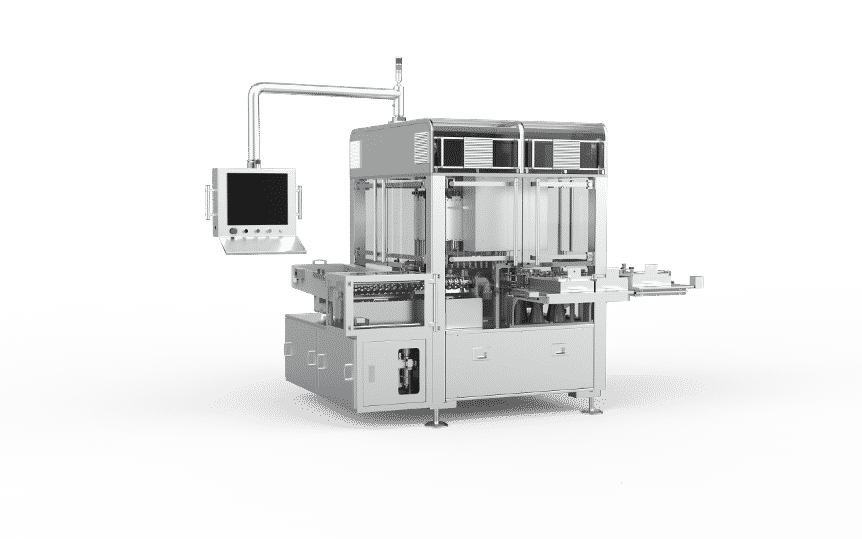

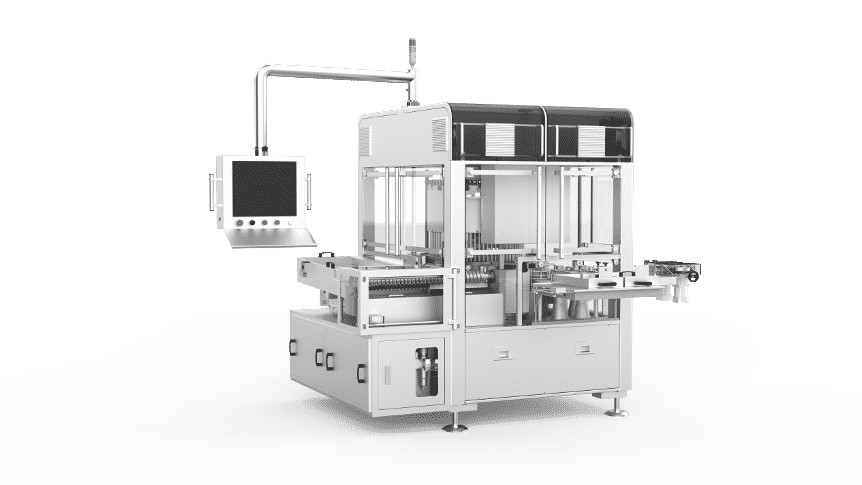

Pharmapack’s Inspection Machine

Pharmapack as an excellent leader in the pharmaceutical packaging industry, it keeps on providing the pharmaceutical industry with cost-effective packaging equipment, and inspection machines of them are one good choice for the pharmaceutical industry.

● High Detection Accuracy; Precise and Reliable

The inspection machines of Pharmapack are highly accurate because their detection machine has a state-of-the-art high-speed camera with a speed of 300 frames per second. High speed and high-quality image acquisition can clearly see foreign bodies in every item. For example, the LFIM-60/84 Continuous Inspection Machine of Pharmapack is made of imported stainless steel and special materials in accordance with GMP specifications. And each camera of the machine is equipped with a high-speed DSP image processing system jointly developed by Pharmapack Italy and the headquarters research and development team. With the latest technology, the speed of inspection is greatly improved.

● High Efficiency

The inspection machines of Pharmapack have an innovative structure, and the electric cabinet is installed on top of the machine and covers the sealing of the operating station. In this way, the machine can guarantee that there will be no leakage even if the bottle is damaged. The structure helps to improve work efficiency. The smart inspection packaging line of Pharmapack includes an inspection machine, labeler, and tray loading machine. An integrated application which achieves automatic packaging line is conducive to improving product quality, reducing labor costs, creating maximum value for customers

● Automatic Rejection of Defective Products

Pharmapack’s machines have a reliable inspection system to ensure particle detection effectiveness and system stability. It comprises a German industrial camera and a multi-core DSP image processing board. Each camera detection station can capture and effectively process multiple images. With a high-speed camera and a high-performance intelligent recognition system, the inspection machine can quickly and accurately identify defective products and then automatically reject them. Defective products are eliminated in three ways, and users can accurately control upstream operations by eliminating the number of items in each elimination category.

● Capability

The inspection machine is capable of cap top surface, liquid level, alu crimping, particle, and crack inspection. And particle inspection is the core technology of the detection machine. The particle inspection process of the inspection machine is as follows: bottle feeding, rotating bottle, emergency stop, image acquire, calculation, sorter. The whole process also requires high-speed cameras to capture images and then analyze them through special image processing algorithms to determine the quality.

● Customized Service Available

Pharmapack provides personalized solutions based on the data and requests provided by different customers. They have pre-sales and after-sales service centers in Asia, Europe, and North America, with a professional 24-hour online customer service team ready to design, debug, maintain, or upgrade solutions.

In Conclusion

All in all, the inspection precision of the machine, efficiency of the machine, the risk of false reject, technology capability, and customized service are the five top things customers in the pharmaceutical industry should consider when buying inspection machines. And Pharmapack, a professional company in pharmaceutical packaging machinery, is the best choice of inspection machines.