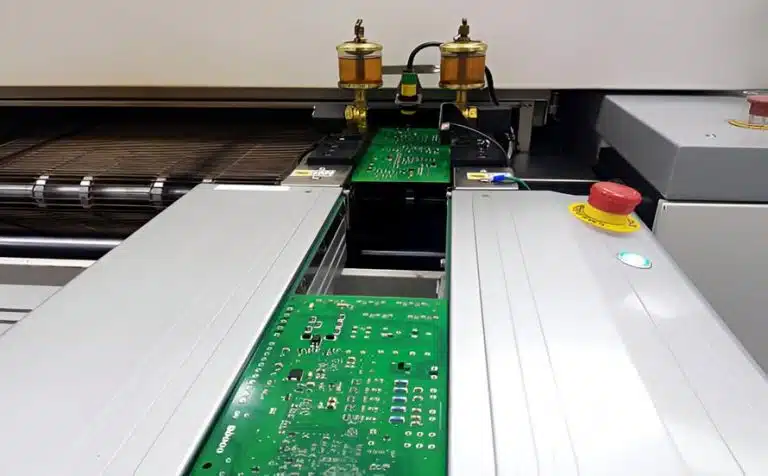

Lead free PCB assembly is the process of manufacturing printed circuit boards without using lead-based solder. Traditional soldering methods often rely on tin-lead alloys, but increasing environmental regulations and health concerns have driven the adoption of lead-free alternatives. Lead free PCB assembly uses materials such as tin-silver-copper (SAC) alloys to create safe, reliable solder joints while complying with global directives like RoHS (Restriction of Hazardous Substances).

This assembly method is essential for producing electronics that meet environmental standards without compromising performance. Lead free PCB assembly is used in a wide range of applications, from consumer electronics to industrial, automotive, and medical devices.

Contents

Importance of Lead Free PCB Assembly

The shift to lead free PCB assembly is critical for environmental sustainability and regulatory compliance. Lead is toxic and can accumulate in living organisms, posing serious health and environmental risks. By eliminating lead from PCB assembly, manufacturers contribute to safer electronics and reduce the ecological impact of discarded devices.

Lead free assemblies are not only safer but also increasingly required by legislation in major markets, including Europe, North America, and parts of Asia. Compliance with these regulations ensures that products can be sold globally while maintaining high-quality and reliable electronic performance.

Advantages of Lead Free PCB Assembly

Lead free PCB assembly offers multiple advantages for manufacturers and end-users:

- Environmental Safety – Eliminates toxic lead from solder joints, reducing health and ecological risks.

- Regulatory Compliance – Meets RoHS and other international environmental standards, ensuring market accessibility.

- Durable and Reliable – Modern lead-free alloys provide strong mechanical strength and thermal stability for long-lasting performance.

- High-Temperature Resistance – Lead-free solder can withstand higher operating temperatures, suitable for high-power applications.

- Market Acceptance – Products assembled with lead-free techniques are widely accepted in industries prioritizing sustainability and safety.

Applications of Lead Free PCB Assembly

Lead free PCB assembly is used across multiple sectors due to its reliability and compliance with safety regulations.

In consumer electronics, lead-free assemblies are utilized in smartphones, laptops, tablets, and smart home devices, where product safety and longevity are critical.

In the automotive industry, lead-free PCB assemblies are applied to control modules, infotainment systems, and lighting solutions, supporting high reliability under harsh environmental conditions.

The medical sector relies on lead-free PCB assemblies for diagnostic devices, monitoring systems, and portable medical instruments, ensuring safety and compliance with health regulations.

In industrial electronics, lead-free assemblies are used in automation equipment, power control systems, and communication devices, providing durability and environmental safety.

Challenges in Lead Free PCB Assembly

Although lead free PCB assembly is essential, it presents certain challenges. Lead-free solder has a higher melting point than traditional tin-lead alloys, which can introduce thermal stress during the assembly process. Components, substrates, and boards must be able to withstand elevated temperatures without damage.

Additionally, lead-free solder can sometimes form brittle joints if not handled correctly, requiring precise temperature control and advanced soldering techniques. Skilled technicians and reliable manufacturing processes are crucial to overcome these challenges while maintaining high-quality performance.

Future of Lead Free PCB Assembly

As environmental concerns and regulatory requirements continue to grow, lead free PCB assembly will remain a standard practice in electronics manufacturing. Emerging applications such as IoT devices, 5G communications, wearable electronics, automotive EV systems, and medical technology will increasingly rely on lead-free assemblies.

Advances in lead-free materials, soldering technology, and automated assembly processes will enhance reliability, efficiency, and scalability. Manufacturers who adopt these technologies will be well-positioned to meet evolving market demands while contributing to a greener, safer electronics industry.

Conclusion

Lead free PCB assembly plays a crucial role in producing safe, sustainable, and reliable electronic products. From consumer devices to automotive, medical, and industrial applications, lead-free assemblies ensure compliance with environmental regulations while maintaining optimal performance and durability.

For companies seeking high-quality manufacturing and eco-friendly solutions, partnering with an experienced printed circuit board assembler ensures precise assembly, regulatory compliance, and consistent reliability from prototype to full-scale production.