In the world of manufacturing, pipe extrusion is a cornerstone process, producing essential components for various industries. This article explores the diverse materials used in pipe extrusion and their unique advantages, highlighting why outsourcing this specialized process is becoming increasingly popular.

Contents

Understanding Pipe Extrusion

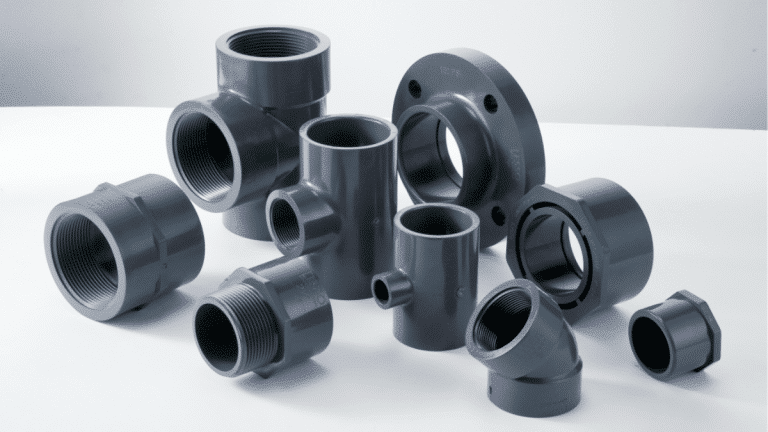

Pipe extrusion is a manufacturing technique in which raw material is melted and forced through a die to create a continuous length of pipe. This versatile process works with a range of materials, each offering distinct benefits for different applications.

Materials Used in Pipe Extrusion

Pipe extrusion involves much more than just plastic; a variety of materials can be used:

- Polyethylene (PE)

Polyethylene, particularly High-Density Polyethylene (HDPE), is widely used in pipe extrusion. It offers excellent chemical resistance, flexibility, and durability. PE pipes are ideal for water supply, gas distribution, and sewage systems. Their lightweight nature makes installation easier and more cost-effective. - Polyvinyl Chloride (PVC)

PVC is another popular choice for pipe extrusion. It provides high strength, rigidity, and excellent resistance to chemicals and corrosion. PVC pipes are commonly used in plumbing, irrigation, and electrical conduits. They offer a long service life and are relatively inexpensive to produce. - Polypropylene (PP)

Polypropylene pipes excel in high-temperature applications. They offer good chemical resistance and are lighter than many alternatives. PP pipes are often used in industrial processes, chemical plants, and some plumbing applications where heat resistance is crucial. - Cross-linked Polyethylene (PEX)

PEX combines the flexibility of PE with improved strength and temperature resistance. It is becoming increasingly popular in residential plumbing for both hot and cold-water lines. PEX pipes are resistant to scale and chlorine and can withstand freezing temperatures better than many other materials. - Acrylonitrile Butadiene Styrene (ABS)

ABS pipes are known for their high impact strength and good temperature resistance. They are often used in drain-waste-vent (DWV) systems and some industrial applications. ABS is relatively easy to install and offers good sound-dampening properties. - Metal Alloys

While less common, some specialized applications use metal alloys in pipe extrusion. Materials like aluminum or copper alloys can be extruded for specific industrial or high-performance needs, offering excellent heat conductivity and strength.

Advantages of Pipe Extrusion

Given the specialized nature of pipe extrusion and the variety of materials involved, many companies are turning to outsourcing or purchasing extruders from specialized companies. This approach offers several benefits, such as access to specialized expertise: outsourcing partners often have deep knowledge of various materials and extrusion techniques, ensuring optimal product quality.

Another advantage of working with pipe extrusion professionals is cost efficiency. By leveraging the economies of scale of specialized manufacturers, companies can reduce their production costs.

Extrusion professionals also ensure quality through robust quality control processes and aid in selecting the best materials and extruders specifically suited for product design and development.

We hope this article provided some clarity on the different materials used for pipe extrusion. If you need more in-depth information, consider contacting the best extrusion companies.